Indasteri ea lijo e tlas'a khatello e ntseng e eketseha ea ho finyella litlhoko tsa baahi ba lefatše ba ntseng ba eketseha ka metseng e meholo.YODEE e na le potefolio e pharaletseng ea sehlahisoa e koahelang lisebelisoa tsohle tsa tlhahiso ea lijo.Ho tloha lits'ebetsong tse tloaelehileng tsa feme ho ea ho litharollo tse tloaelehileng, mekhoa eohle ea theknoloji ea lijo ea YODEE e etselitsoe ho finyella litekanyetso tse molemo ka ho fetisisa tsa bohloeki le boleng ha e ntse e sebetsa ka katleho le ka mokhoa o tsitsitseng ho thusa bareki ba rona ho finyella tlhahiso ea lijo e feto-fetohang le e theko e tlaase.

Ka mohlala, li-thickeners tse kang marenene le starch li sebelisoa lihlahisoa tse nang le mafura a tlaase ho nka sebaka sa viscosity le phello ea ho ruruha ha oli, ho matlafatsa molomo, le ho netefatsa emulsion e tsitsitseng.

Hangata tlhahiso e kholo e etsoa ho sebelisoa lifeme tse entsoeng ka ho khetheha, ts'ebetso e etsoa ka mokhoa o ikemetseng 'me tlhahiso e etsoa tlas'a vacuum.Bakeng sa R & D e tloaelehileng, tlhahiso ea lifofane le tse nyenyane tsa 'maraka o "itokiselitseng ho sebelisoa" - tsela eo mayonnaise e hlahisoang ka eona e hloka ho feto-fetoha ha maemo, haholo-holo ha ho fetola litlolo.

Tse ling tsa diresepe tse tloaelehileng ke tse latelang:

| 80%Foromo ea oli | Foromo ea Mafura a Tlase | ||

| Oli ea meroho | 80% | Oli ea meroho | 50% |

| Yolk ea lehe | 6% | Yolk ea lehe | 4% |

| Li-thickeners tse ling | 4% | ||

| Asene | 4% | Asene | 3% |

| Tsoekere | 1% | Tsoekere | 1.5% |

| Letsoai | 1% | Letsoai | 0.7% |

| Linoko (mohlala, mosetareta) | 0.5% | Linoko | 1.5% |

| Metsi | 7.5% | Metsi | 35.3% |

Mokhahlelong oa pele oa tlhahiso, mahe, a ka sebelisoang ka mokhoa oa metsi kapa oa phofo, a qhalakanngoa ka metsing.Sena se sebetsa joalo ka emulsifier.

Metsoako e setseng e tsoelang pele ea mokhahlelo e ntan'o eketsoa ebe e tsoakoa ho fihlela e qhalakantsoe ebile e na le metsi.

Oli e eketsoa ka potlako ha karolo e tsoelang pele e monya oli.Sena se lebisa ho phahama ho hoholo ha viscosity ea sehlahisoa ha emulsion e theha

Potso:

Metsoako e tsoelang pele ea mokhahlelo e etsa karolo e nyane feela ea sebopeho ka kakaretso, empa e bapala karolo ea bohlokoa.Thepa ea ho kopanya e tlameha ho khona ho qhalakanya hantle le ho nosetsa lintho tsena ka metsi a batlang a le tlaase.Haeba mahe le li-emulsifiers tse ling li sa hasane hantle 'me li na le metsi, emulsion e ka' na ea robeha nakong ea ho eketsa oli.

Hydration ea stabilizers le thickeners ke e 'ngoe ea mesebetsi e thata ka ho fetisisa ea ho kopanya.Tharollo e ka 'na ea tlameha ho ts'oaroa nako e telele ho qeta metsi.Ho bonolo ho etsa li-clumps;tsena li ke ke tsa rarolloa ka pherekano feela.

Ka lebaka la karolo e phahameng ea oli ka foromo, emulsion e ka 'na ea robeha haeba oli e sa ekeletsoe mohato o tsoelang pele hantle.Sena se thata ho laola ha o eketsa oli ka letsoho.

Marotholi a karolo ea oli a tlameha ho fokotsoa ho isa boholo bo bonyenyane ka ho fetisisa bo ka khonehang ho eketsa sebaka sa oli sebakeng se tsoelang pele ho netefatsa emulsion e tsitsitseng.Sena ha se bonolo ho se fihlela ntle le lisebelisoa tse khethehileng.

Aeration e tlameha ho fokotsoa kapa e felisoe ho eketsa bophelo ba lihlahisoa.

Mokhoa oa tlhahiso:

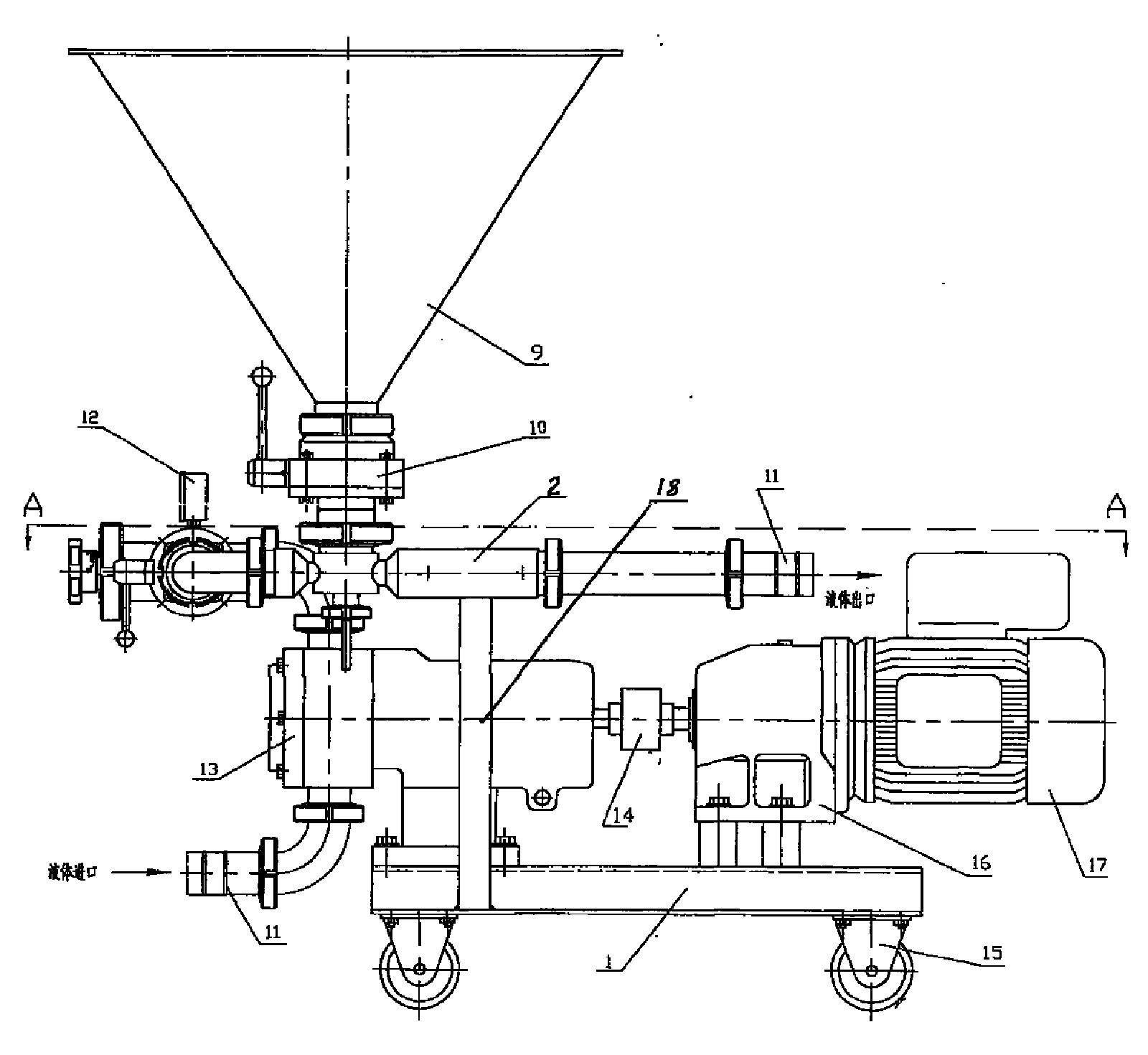

1. Metsi a khutlisetsoa ho tloha sekepeng ka tsamaiso ka mochine o entsoeng ka ho khetheha oa mohala.Mahe (phofo kapa mokelikeli) a kenngoa ka har'a setshelo 'me a kolobisoa ka potlako le ho hasana ka har'a metsi a phallang ka lebelo le phahameng.

2. Ebe u eketsa lisebelisoa tse setseng tsa karolo ea metsi ho setshelo.Recirculation e tsoela pele ho fihlela metsoako e qhalakanngoa ka ho feletseng 'me e le metsi.

3. Belofo ea ho kena ka oli ea bula 'me oli e pompeloa ho tloha ho hopper ho ea karolong ea metsi ka lebelo le laoloang.Likarolo tsa karolo ea metsi le oli li kena ka ho toba hloohong e sebetsang ea motsoako oa inline, moo li nang le ho kuta ho matla ho phahameng.Sena se hasanya oli hantle karolong ea metsi, ho etsa emulsion hang-hang.Asene (le / kapa lero la lemone) e kenngoa ka oli ea ho qetela.

4. Ho tsosolosoa ha sehlahisoa ho ntse ho tsoela pele ho etsa bonnete ba hore ho tšoana ho tšoanang ha viscosity e ntse e eketseha.Kamora nako e khuts'oane ea ho potoloha, ts'ebetso e felile 'me sehlahisoa se felileng sea lokolloa.

Molemo:

E ntle bakeng sa lihlopha tse nyenyane bakeng sa tšebeliso ea hang-hang.

Fokotsa moea.

Sistimi e batla e felisa phoso ea opareitara.

E fana ka botsitso ba batch-to-batch le botsitso ba mayonnaise e hlahisoang ke feme ea turnkey ntle le litšenyehelo tse phahameng tsa chelete.

Kaha motenya o na le metsi ka ho feletseng 'me lisebelisoa tse ling li hasane hantle, lihlahisoa tsa lihlahisoa tse tala li eketseha.

Sistimi e etselitsoe ho sebetsana le lihlahisoa tse phahameng tsa viscosity ntle le tlhoko ea lipompo tse eketsehileng kapa lisebelisoa tse thusang.

Ho ikamahanya habonolo le liphetoho tsa mofuta oa sehlahisoa le sebopeho.

YODEE e boetse e ts'ehetsa moralo, tlhahiso, lipalangoang, ho kenya le ho lokisa lisebelisoa tse latelang tsa mela e meholo e ikemetseng ea tlhahiso e felletseng ea indasteri.Lihlahisoa tsa sehlopha sa lijo hangata ke mayonnaise, moaparo oa salate, mosetareta, mahe a linotsi le lihlahisoa tse ling.Litlhoko tsa ts'ebetso li re etsa Litlhoko tsa thepa ea mochine li thata haholoanyane, 'me boemo ba lijo SUS304 tšepe e sa hloekang le boemo ba lijo SUS316L e lokela ho sebelisoa e le thepa e ka sehloohong ea mochine.Homogenization, emulsification, ho susumetsa le ho paka ka thepa ea lijo ke tsa bohlokoa ka ho khetheha.

Bakeng sa lisebelisoa tse tšehetsang prouct le data ea tekheniki, ka kopo ikopanye le basebetsi ba khoebo ba amanang le YODEE.